Almost all the building materials used in the sites are purchased in industrialised form, as a finished product. They were manufactured by a factory, for example: steel/concrete reinforcements, bricks, coverings, plasterboards, OSB, doors, windows etc. The same working system must also be applied for the wooden structures, which can be executed in a specialised production unit and delivered to the site in a packaged system. Thus, all the elements of the wooden structure are prepared in the factory in the form of lattices or rafters cut to size. The classical method of building wooden structures directly on the site, from raw timber, must be abandoned.

Benefits:

The waste of wood material is reduced

Short execution time

Wood quality through drying and treatment

Larger living space

Money saving

Materials used

Dried and treated timber:

The high temperature in the drying chambers removes all harmful insects from the wood.The use of green wood creates unfavourable conditions for insect development. Using dried timber, the risk of harmful fungi and mildew is much lower.

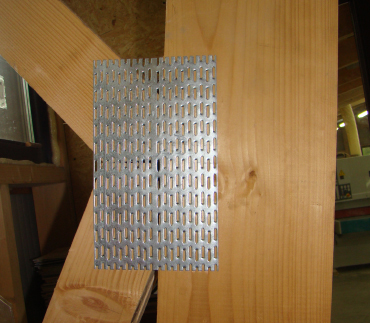

Multi-nail connectors

The technology of prefabricating industrialised wood structures, assembled with multi-nail boards, is widespread in the western part of Europe and in the Scandinavian countries. In Europe, France is the largest manufacturer of prefabricated twood structures assembled with multi-nail boards.In 2006, Romania joined the Mitek group. From then on, more and more constructions are made in industrialised system.

All are approved according to EN14545:2008 ‘Timber structures. Connectors. Requirements.’

Connecting systems - Posi strut

The prefabricated lattices are made from dry timber, quality class and resistance between C18 and C24, according to Eurocode for sawn timber.Before the wood enters the production process, a rigorous sorting is done and the defective and twisted elements are eliminated. If the wood elements are defective, this will come to light during drying and will be removed on sorting. The use of wood that is wet and that has large sections creates the risk that some elements will twist (bend) over time, after the framework has been mounted, problems may occur on the walls and ceilings plated with plasterboard.

OSB boards

OSB 4 TOP boards are boards for wooden constructions without formaldehyde content, with static and physical characteristics of optimal constructions, having German approval for use in constructions Z-9.1-566. For the production of boards with thicknesses up to 40 mm, only resinous wooden chips are used in the surface layers, which gives the panels superior technical characteristics.They are used for prefabricated house construction, commercial construction, passive house construction, dry and wet area

Benefits:

- High resistance to very high loads

- Very high dimensional stability

- Vapour barrier

- Airtight

- High edge strength

DHF boards

Roof boarding with rain-proof protectionDHF is a moisture-resistant, vapour-permeable fibreboard, CE marked according to EN 14964 and with German approval Z-9.1-454 for use with a load-bearing role. Wood powder and sawdust from timber production are used for its production. The boards are glued with non-formaldehyde resin and delivered in thicknesses of 15 and 20 mm.

They are used for: Outer panelling, with stiffening role, Weather resistant protection, Frameworks roof boarding with large distances between rafters

Benefits

Vapour permeable

Technical class UDP-A

They can be delivered in optimal sizes for roof and wall

Wind tight

UV-resistant

Resistant to hail